We are often contacted by business start ups, who might be new to shoe design, or fashion or design students, who may not be familiar with the footwear design process. We have written this section to help explain the procedure. If you have any questions or comments, please

contact us.

Meet with Client

We prefer to meet you first to discuss the project, but nowadays we're mostly meeting online, Google Meet/Skype/Whatsapp/Zoom etc, up to you. We discuss the requirements: What kind of shoes, where they will be made, which parts of the footwear design process does the client require from us? Every shoe design project is different and we understand that not every client needs us to cover every single part of the process.

Pre-work/Research/Evaluation

Until we know what's out there, we don't know where your footwear concept will sit, whether there's a market for it, what to charge or whether your USP really is unique. So pre-work, before we begin design, is super important. Perhaps you're not sure if we're going to be a good fit for your brand? That's ok, we can do the pre work as a project on its own, we can include sketches if you want, and agree a price just for that.

When we research, we analyse the category in depth, does it already exist? In what markets? At what prices? We also analyse trends, breaking them down into materials, colours, toe shapes, heels etc. We may also make sketches. This can be put together into a report format, where we highlight and group the trends so they are easy to understand.

For some projects, research may take place in art galleries, libraries or anywhere else we may wish to find inspiration outside of the footwear design world, to get our creative juices flowing.

Story/Mood Boards

This is a visual representation of a new fashion trend, sometimes called 'Mood Boards' because they describe the 'mood' of a trend. The storyboard is used by the footwear designer to 'set the scene', before they start designing. It is often used by fashion clients to understand a trend, or to explain a trend to a colleague. It can help a client decide the focus of a range of footwear, if it is relevant to their customer before the designer starts to design.

Storyboards are usually made from fashion magazine editorial, they may include notes, material swatches, other inspirational pictures, sketches or photos. There is usually an element of forecasting involved. We look at current trends, we look at what the opinion formers are doing and wearing, we look at what is happening in the world generally and use this information to predict what might be popular next.

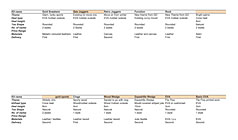

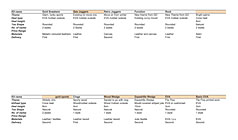

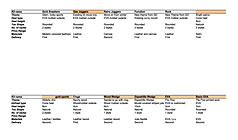

Range Plan

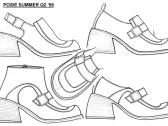

If we are developing a range of shoes for a customer, we propose to make a range plan before we start to design. This is a plan to work out how many outsoles, styles and colours and what price points we want to achieve. Visual representations are often included, they may be thumbnail (i.e. small) sketches, they could be photos of similar product. As the design work progresses, the range plan is edited.

The Design Brief

We do not always receive a full design brief from a client, so do not be afraid if you are not quite sure what you require! Some or all of the previous steps in the design process that we have outlined so far, will naturally lead you to the design brief. A design brief would usually describe the customer for the product, are they male, female, age, perhaps the magazines they read, their lifestyle. A description of where the shoes will be sold, perhaps is it a website, or a fashion store for instance. We will need to know the target price for the product, the intended factory, the factory capabilities (if we know at this stage), possibly more specific instructions - i.e. wedge outsole, stiletto heel, round toe, or in the case of sports, the end use of the product.

Initial Ideas

Working on ipad pro, we figure out our concepts quickly, starting with lots of scribbles and small sketches. We upload them to a shared album, icloud, dropbox or google drive, anywhere we and the client can make comments, once we've agreed with the client which are the strongest and if there are any amendments to be made we make more detailed digital sketches which are uploaded and discussed again.

Last/Heel/Outsole

Some clients require the entire product to be developed from scratch:

Last development

The last is a plastic, wooden or metal, form. It is the equivalent of the tailors dummy, and almost all shoes are made on a last. The last dictates the toe shape and the heel height. They come in pairs and different sizes and widths, just like feet!

If required we can make sketches and visit a last maker to have a prototype made (carved by hand from wood), alternatively, we can select a shoe already in existence and submit it to a last maker to make a replica which we can then use to develop our own designs.

Heel development

If required we can write full specs for new heel designs. We can also have wooden models made for approval and for the heel mould makers reference, before we make production.

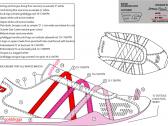

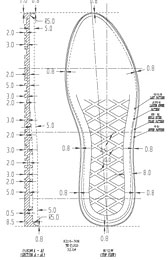

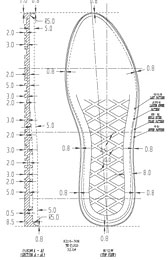

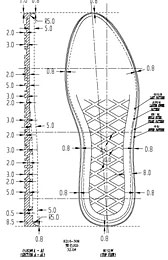

Outsole development

We can design any kind of outsole, in any kind of material. As with heels, we can also have models made for your approval. We now collaborate with a design studio to make blueprints and rapid prototypes of more complext/sporty outsoles.

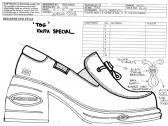

Full Colour Renders

Once we have liased with the client regarding our initial ideas, we then take any comments onboard and in Procreate, we make more realistic full colour designs, to give a more realistic representation of the shoe. When these are signed off by the client, we make vector artwork, using Adobe Illustrator, in black and white, showing lateral and medial views, front and back and top views as needed.

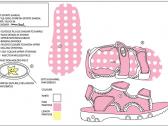

Tech pack

The full colour renders have been approved, it's time to complete the tech pack. This folder contains the documents which are the instructions to the factory to make the shoe. Some clients require us to work on this stage only. Perhaps they have firm ideas of the product they want, they can already provide sketches, or they need an interpretation of product /trends that already exist, but need help with tech packs. We sometimes are contacted by inventors who need specifications for their ideas writing in order to file a patent application, this is a slightly different document to a tech pack but we have the experience and skills in order to do this.

Pattern Cutting

Although we do have an understanding of pattern cutting, we do not provide a pattern cutting service because most factories provide this as part of their service. We can put the client in touch with an expert pattern cutter or coordinate the task with them ourselves, if required.

Briefing In

We can contact the factory sample room on our clients behalf and follow up on all development if requested. We can also visit the factory by arrangement with the client. Sometimes a simple email cover note sent along with the specifications is all that is required. Other factories require much more information than that.

Samples Received/Amendments

Once first prototypes are received we often review them with the client. There are almost always improvements to be made. Some clients prefer us not to be involved after this stage, making any comments and amendments to the factories themselves. If you're not a footwear trade expert then we strongly recommend that you involve us through the whole process to final, production sample.

Colourways / Material Combinations

The client may request the shoe to be available in more than one colour or material choice. We generally do this after we have received a prototype that we are happy with. We use Adobe Capture to make swatches from your colour cards, we then make several colour renders showing these suggestions, the client then chooses and we add to the tech packs and order the colourways.

Final Sample

Once we have all the prototypes and we are happy with them, the client is free to order sales samples, place production, etc.

Following Season

The design process does not end at final sample stage. Once the client has experienced sell-in (samples shown to store buyers who then write orders) and sell-through (shoe sells to end consumer), they usually require new versions of the best sellers. This can be a simple colour or material update or a move-on (similar style) for the best seller.

(to top)

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()